Industrial-Strength Formwork Solutions for High-Performance Concrete Casting

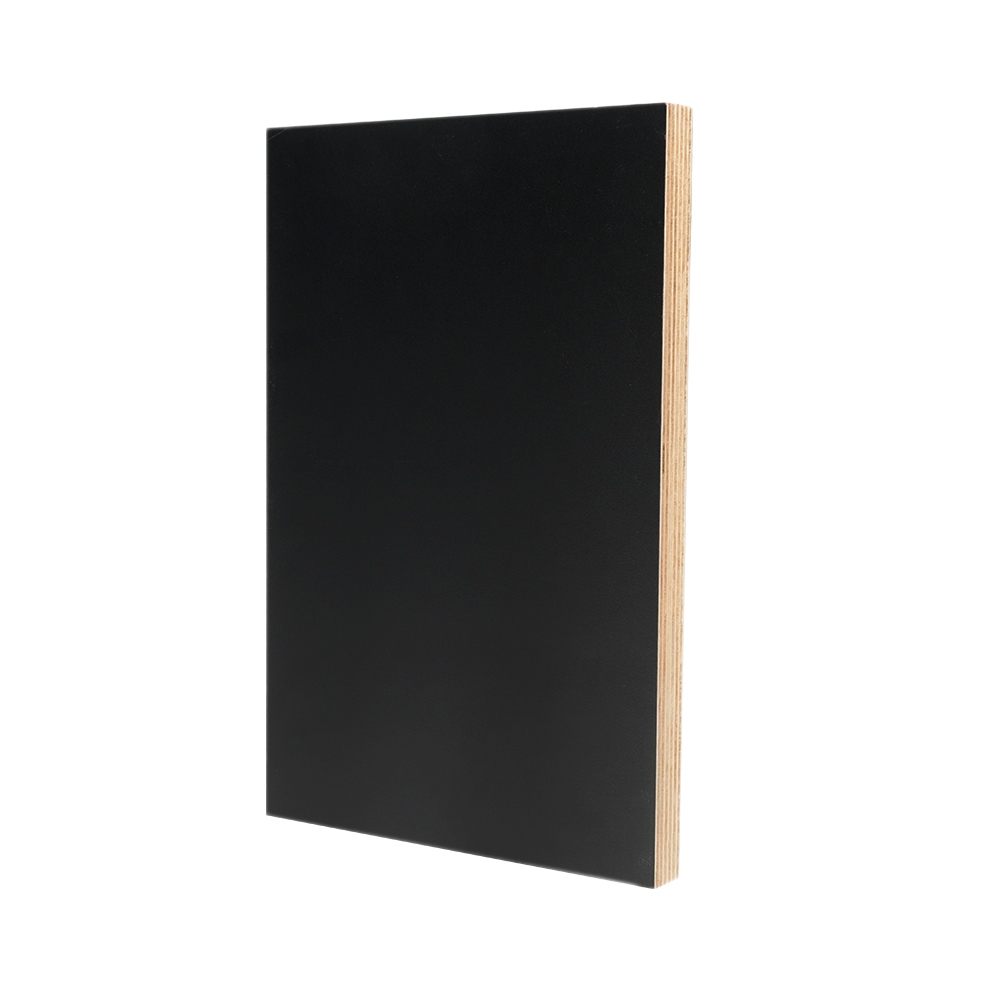

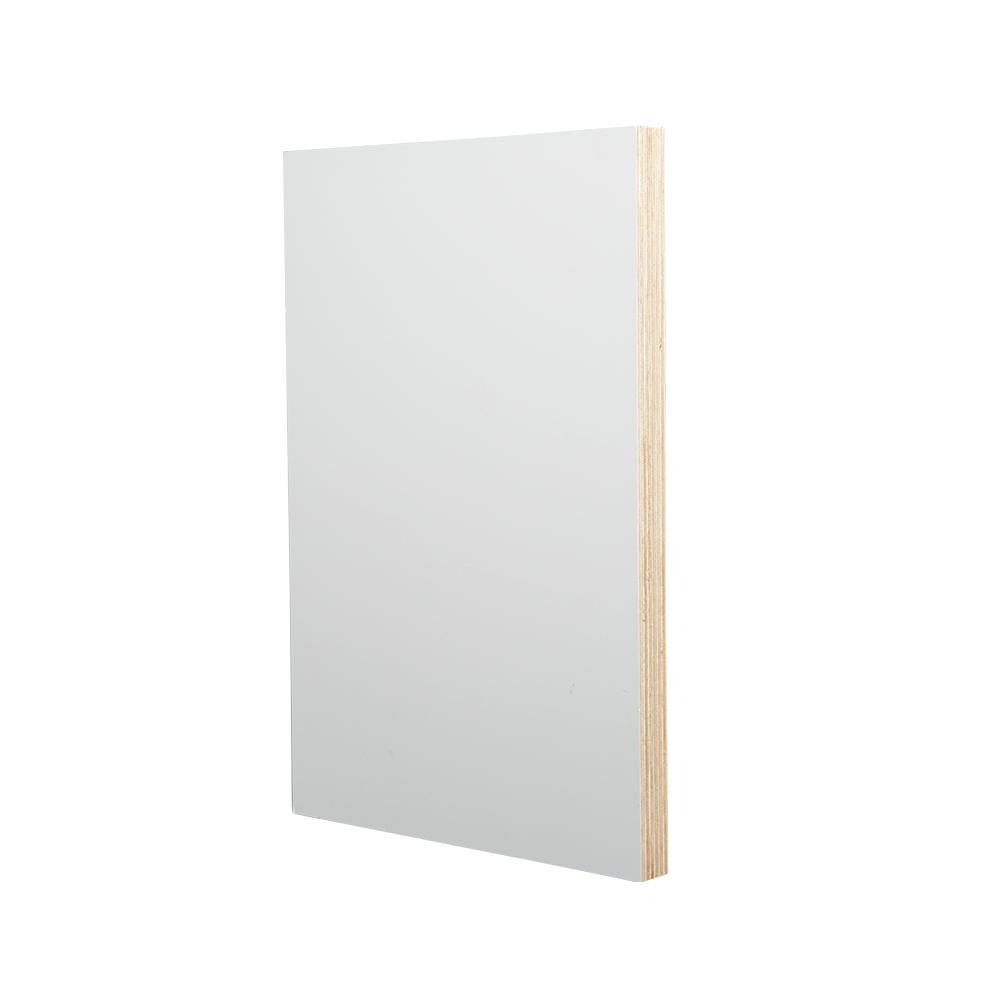

Shuttering Panel, the critical backbone of the concrete construction industry, is engineered to provide the essential temporary structure required to mold wet concrete into its final architectural form. Our high-performance Shuttering Panels are specifically designed for professional contractors who demand a product that can withstand the immense hydrostatic pressure of large-scale concrete pours while maintaining absolute dimensional accuracy. Unlike basic plywood, these panels are treated with a heavy-duty phenolic resin coating that creates a chemically resistant barrier, protecting the internal wood fibers from the corrosive effects of wet cement and ensuring a smooth, predictable finish for every cast.

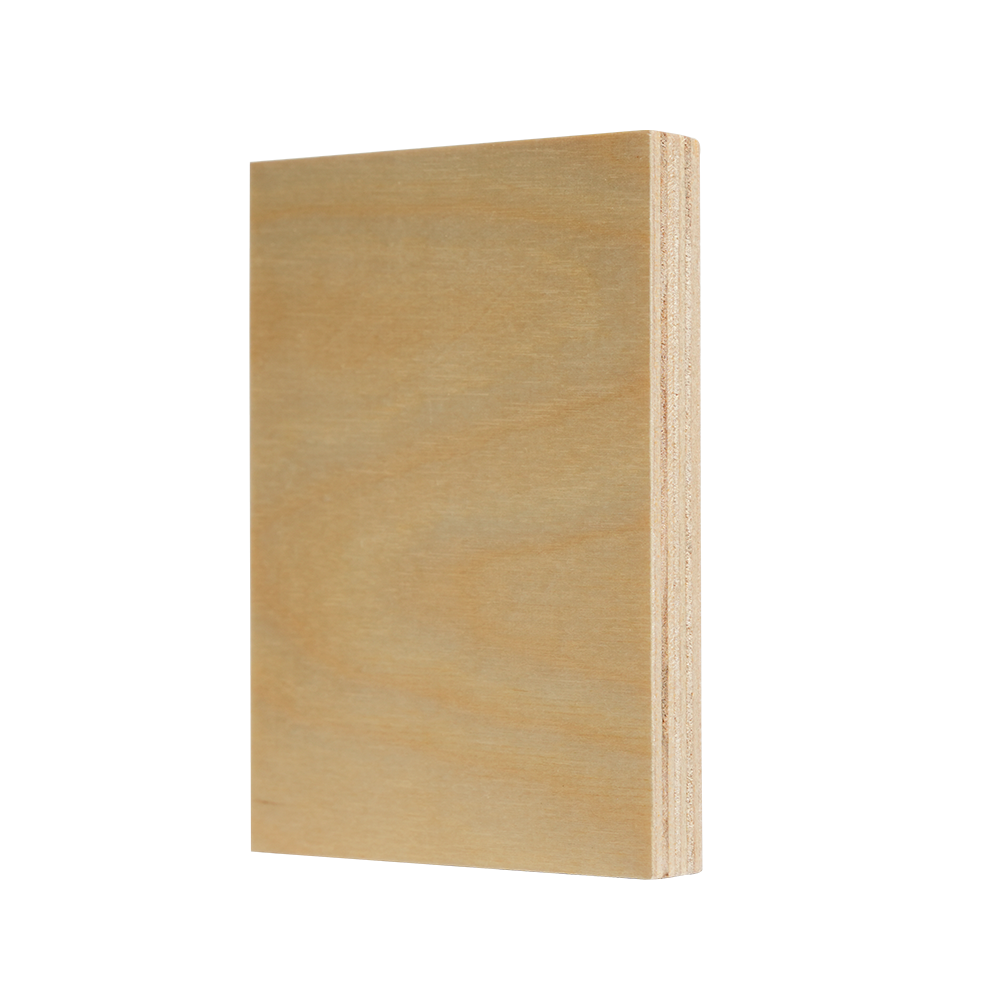

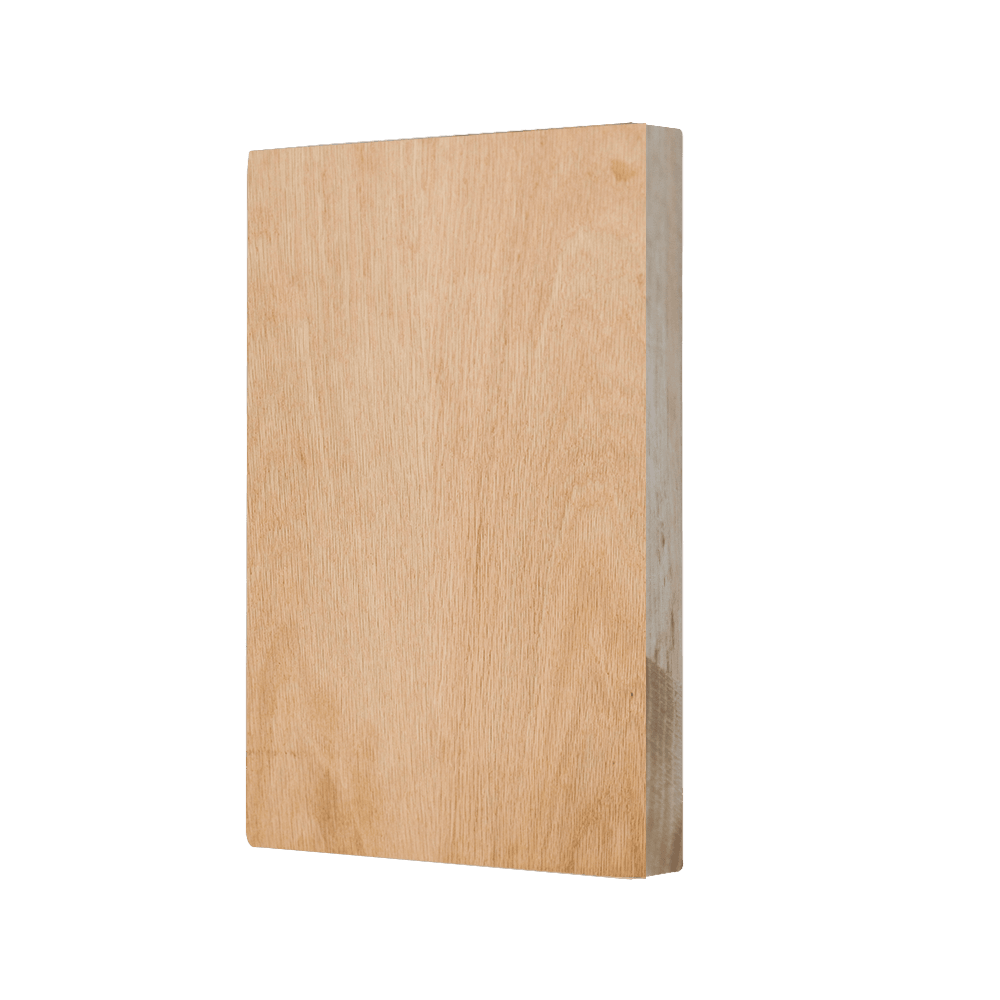

The structural heart of our shuttering panel is a cross-laminated core, primarily utilizing high-density birch or premium combi-wood veneers. This multi-layer construction is bonded under extreme heat using Water Boil Proof (WBP) adhesives, which are essential for maintaining panel integrity in the wet, humid, and often grueling conditions of a construction site. The edges of each panel are factory-sealed with a specialized waterproof acrylic coating, a vital feature that prevents moisture ingress, edge-swelling, and the eventual delamination that plagues lower-quality alternatives. This attention to detail translates directly into a higher number of "pours" per sheet, maximizing the return on investment for construction firms.

Efficiency on-site is a key driver in the design of our Shuttering Panels. The smooth, low-friction surface allows for a clean release from the cured concrete, significantly reducing the time and labor required for stripping the formwork and cleaning the panels for the next use. This also results in a superior concrete surface (fair-faced concrete), which often requires minimal to no additional finishing work, such as plastering or grinding. For large-scale projects like high-rise buildings, bridge decks, and infrastructure developments, the reliability of our shuttering panels ensures that project timelines are met without the costly delays caused by material failure.

At the intersection of safety and performance, our panels are tested to meet international standards for load-bearing capacity and rigidity. We understand that on a job site, the shuttering panel is more than just a material; it is a critical safety component of the formwork system. By providing a product with a high modulus of elasticity and superior impact resistance, we ensure that our Shuttering Panels provide a stable, safe, and efficient platform for the creation of tomorrow’s infrastructure. From residential slabs to massive industrial dams, our panels deliver the strength you need for every pour.

English

English 中文简体

中文简体