Birch Plywood is made of multiple 1.5mm layers of birch veneer through a special gluing process. Birch has the characteristics of high density, solid texture, and corrosion resistance, so the plywood made of birch has the corresponding advantages.

01

Tianma Lvjian offers basic format dimensions of 5x10, 4x8x4, and 5x5 feet, along with various derived formats that are widely popular in the market.

1525x1525

5x5

1220x2440; 1250x2500

4x8

1220x3050; 1250x3050

4x10

1500x2500; 1525x2500;

5x8

1500x3000; 1525x3050

5x10

02

03

04

Basic definition and structural compositionBlock Board is a man-made board with natural wood strips as the core material and two layers of veneer hot-pressed on the outside. The core material is usual...

View MoreBlock Board is a man-made board made of natural wood core strips and two layers of veneer glued together. Adhesive plays a vital role in the structure of Block Board. It not only determines the bondin...

View MorePerformance requirements of edge banding coatingsEdge banding coatings must have the following basic performance indicators:Excellent waterproofness to prevent moisture and water from penetrating into...

View MoreIn the modern construction and furniture manufacturing industry, the surface treatment performance of plywood plays a vital role in the overall quality and application effect of the product. Tianma Lvjian, as a professional birch plywood manufacturer located in Nantong, Jiangsu Province, is committed to providing high-performance birch plywood products to meet the diversified needs of the market with its advanced production technology and strict quality control.

The surface smoothness of birch plywood is one of its most notable features. The finely processed surface not only improves the beauty of the plywood, but also lays a good foundation for subsequent painting, veneer and other surface treatment processes. Compared with other types of plywood, birch plywood shows superior uniformity during the surface treatment process, significantly reducing problems such as uneven coating, blistering or peeling caused by uneven surface. This excellent surface smoothness provides a solid guarantee for the overall quality of the product.

In terms of coating performance, birch plywood has a strong adhesion between paint and plywood due to its smooth surface characteristics. This property allows birch plywood to better absorb paint and form a uniform and strong coating when applying paint, varnish or other surface coatings. Compared with other types of plywood, birch plywood can better show the color and gloss of the paint, significantly improving the visual effect and market competitiveness of the final product, and meeting consumers' demand for high-quality products.

The surface treatment process of birch plywood also gives it strong stain resistance and wear resistance. The specially treated surface of birch plywood can effectively resist the penetration of stains, reducing the difficulty of cleaning and maintenance. This feature is particularly important in furniture and interior decoration, especially in areas that are prone to pollution such as kitchens and restaurants. In addition, birch plywood has high wear resistance and can withstand friction and wear in daily use, extending the service life of the product and ensuring that it remains in good condition in high-frequency use environments.

Environmental protection is an important consideration for Tianma Green Building when producing birch plywood. The company uses environmentally friendly surface treatment materials and processes to ensure that the products meet the standards of green buildings. This environmental protection feature is not only reflected in the choice of glue, but also in the harmlessness of the surface treatment materials. Compared with some plywoods that use harmful chemicals, birch plywood does not release harmful gases during use, thus effectively ensuring indoor air quality and meeting the modern consumer's pursuit of health and environmental protection.

The surface treatment technology of birch plywood gives it good adaptability in a variety of environmental conditions. Whether in a humid kitchen or a dry living room, birch plywood can effectively resist the impact of environmental changes. This adaptability makes birch plywood widely used in furniture, construction, packaging and interior decoration, fully demonstrating its excellent performance and diverse application potential.

Birch plywood is popular in construction, furniture and many other application fields due to its excellent strength and stability. As a professional birch plywood manufacturer located in Nantong, Jiangsu Province, Tianma Lvjian focuses on the research and development and production of high-performance plywood products to meet the market's growing demand for quality and durability.

Raw material selection

Wood species

The strength of birch plywood mainly comes from the selected raw materials. Birch wood is known for its high density and excellent strength properties. Compared with other woods such as pine and poplar, birch wood performs better in load-bearing capacity and deformation resistance. Therefore, the selection of high-quality birch wood is the basis for ensuring the strength of plywood.

Wood dryness

The moisture content of wood has a direct impact on its strength. Too high moisture content may cause the wood to deform or crack during use, which in turn affects the overall performance of the plywood. Tianma Green Building strictly controls the dryness of wood during the production process to ensure the stability and reliability of plywood in the use environment.

Gluing process

Type of glue

The choice of glue plays a vital role in the strength of birch plywood. Environmentally friendly glue not only provides good adhesion, but also maintains the natural characteristics of wood. Tianma Green Building selects glue that meets green building standards to ensure the best balance between strength and environmental protection.

Number of glue layers

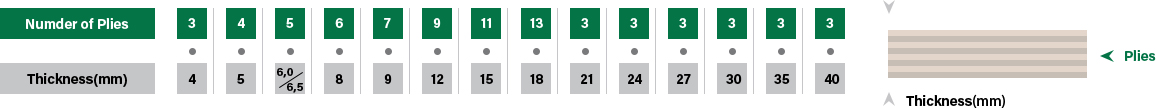

The number of plywood layers directly affects its strength and stability. Generally speaking, the more layers, the higher the load-bearing capacity and overall stability of the plywood. Tianma Green Building's birch plywood adopts a multi-layer glued structure design, which can effectively disperse the external applied pressure and significantly enhance its bearing capacity.

Gluing pressure and temperature

During the gluing process, the applied pressure and temperature have an important influence on the curing effect of the glue. The appropriate pressure and temperature can ensure that the glue fully penetrates into the wood fiber and forms a strong bond. Tianma Green Building strictly controls these parameters during the production process to ensure the excellent performance of plywood.

Processing technology

Cutting and processing accuracy

The cutting and processing accuracy of plywood plays an important role in its strength. Imprecise cutting may lead to loose joints, which in turn affects the gluing effect and reduces strength. Tianma Green Building uses advanced cutting equipment to ensure the processing accuracy of each piece of plywood to improve the overall performance of the product.

Surface treatment

Although surface treatment mainly affects the beauty and durability of plywood, good surface treatment can also enhance its strength to a certain extent. For example, a properly treated surface can effectively resist the intrusion of external moisture and reduce deformation caused by moisture, thereby maintaining its strength.

Environmental factors

Humidity and temperature

The humidity and temperature of the environment have an important influence on the strength of plywood. In a high humidity environment, plywood easily absorbs moisture, resulting in a decrease in strength; while in an extremely dry environment, cracks may appear in the wood, affecting its load-bearing capacity. Therefore, a reasonable storage and use environment is essential to maintain the strength of birch plywood.

Copyright © Tianma Lvjian (Nantong) Wooden Structure Technology Co., Ltd. Rights Reserved.

Wholesale Baltic Birch Plywood Factory